East Frigg

Neptune 7 spudded the East Frigg wildcat on 4 August 1973, and a 56-metre-thick gas-bearing layer was encountered at a depth of 1 915 metres beneath the drill floor. The bit then entered a seven-metre-thick oil zone. The gas-oil interface lay at exactly the same depth as on Frigg. A preliminary production test yielded a flow of 638 000 scm of gas per day. Reserves in the field were put at nine billion scm.

Pioneering research for East Frigg

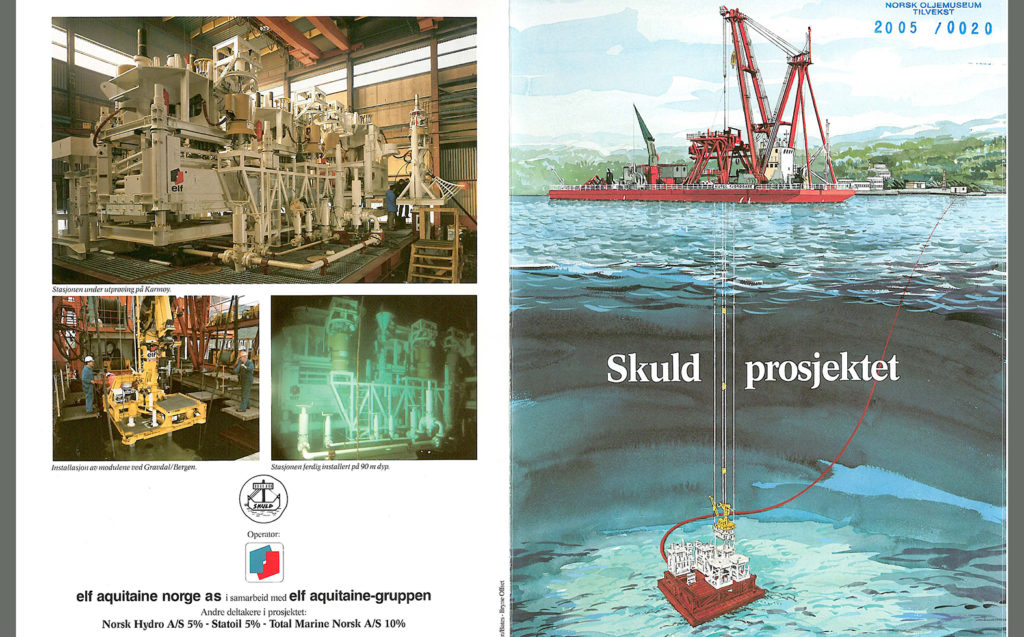

The Norwegian authorities were keen to promote research into alternative offshore development solutions. In that context, Skuld was a government-sponsored research programme which involved a number of large companies and scientific institutes, including Elf, Statoil, Hydro, Kongsberg Våpenfabrikk (KV), the Norwegian Underwater Institute (NUI) and Sintef.

Launched in 1980, the Skuld project sought to demonstrate that subsea installations could be remotely operated over distances of up to 20 kilometres. It also aimed to come up with a totally diverless system. This was pioneering technological development. As part of Skuld, Elf built a simulation station to test the reliability of a remote operation system, gain greater experience with modular solutions and test diverless procedures. The trials consisted of assembling and system-testing a complete production station, first on land, then in 20 metres of water and finally in 90 metres of water without diver assistance. All the trials were conducted with great success. A production life of 20 years was simulated, which also went well. The modular concept, combined with diverless installation procedures, proved a big success. The remote operation system demonstrated its reliability, and the results of the simulation trials showed that a development of East Frigg was commercially viable. The Skuld technology attracted great international attention, primarily for its functional remote control solution and the fact that no diver intervention was required.

On the basis of this Skuld success, Elf launched a new research project in 1987 under the name Super Skuld. Simulation tests of the subsea installations had demonstrated that the equipment could be assembled and was reliable down to a water depth of 90 metres. Super Skuld aimed to test whether the same hardware could be used in 300 metres of water. A test carried out in northern Norway during 1985 showed that this was possible. However, the Skuld concept could only be used on gas wells. Elf accordingly began trials with an oil well version. Two different programmes were launched, one in Norway called Clustoil and the other in Paris under the name Saphire. These designations referred to different oil production solutions, with the first designed for rough-weather areas such as the North, Norwegian and Barents Seas, and the second intended for more benign climates.

East Frigg was developed in close cooperation with the oil division at KV, which later became Kongsberg Offshore. This company was involved not only in the project and testing phase but also at the design and construction stage. The subsea technology used was based on the Skuld and Super Skuld projects.

The field consisted of two separate structures, sometimes designated East and South-East Frigg. With a traditional development approach in 1988, two platforms would have been required. However, experience from the research projects made it possible to position a seabed template on each of the structures. Called production station A (PSA) and B (PSB), these units with their associated equipment and the central manifold station (CMS) were the only installations on East Frigg. They were tied back to Frigg by a gas pipeline, an umbilical with power cables and a hydraulic service line. All production and control functions were operated from QP on the main field via an electrohydraulic system.

Gas from the East Frigg wells passed via the CMS through the pipeline to Frigg TCP2, where a separate module was placed for East Frigg gas reception and for control of the subsea installations. From TCP2, the gas was transported through the Frigg Norwegian Pipeline to St Fergus and sold to British Gas under the Frigg contract.

This project made East Frigg a pioneering field for Elf in technological terms. After North-East Frigg, it was the second subsea development on the NCS with remotely operated wells and the first to be operated entirely without an on-field surface installation.

The field was officially inaugurated by petroleum and energy minister Arne Øien on 18 October 1988. By then, it had already been in test production for several weeks and had begun making contractual gas deliveries to British Gas on 1 October.

East Frigg ceases production

East Frigg was shut down on 22 December 1997 after producing 9.2 billion cubic metres of gas and 625 000 barrels (100 000 scm) of condensate (light oil) over nine years. The five production wells were plugged during the first half of 1999.[REMOVE]Fotnote: Cessation plan, Proposition no 8 (1999-2000) to the Storting, Report no 47 (1999-2000) to the Storting.

Preparations for removing the seabed template were carried out by Coflexip Stena Offshore (CSO), and this structure was retrieved to the surface by Thialf in July 2001. The installation tool and Christmas trees (valve assemblies) were sold, while the protective frame was delivered for melting down and recycling.

| Type |

Three subsea installations East Frigg A with three gas wells East Frigg B with two gas wells East Frigg C Manifold Station |

| Function | Gas production |

| Water depth | 110 meters |

| Geographical postion | 18 km east of Frigg |

| Well control | From QP |

| Process | Module M51 on TCP2 |

| Field discovered | 1973 |

| Production startup | 1988 |

| Closed | 1997 |

| Production quantity | 9,3 billions m3 gas 26400 tons of condensate |